At one time, taking the thousands of pieces of information in a plant and displaying it on some kind of information system was a real challenge and in fact, impossible. With the development of Distributed Control Systems (DCS) it is now easy to take all the information and organize it in a hierarchical system.

DCS displays information on a computer and allows process operators to run the process, making the process information available to other people in the plant. Once the DCS converts the process information to personal computer language, it can be distributed to everyone on the plant site and to other parts of the organization that may be located anywhere in the world.

DCS displays information on a computer and allows process operators to run the process, making the process information available to other people in the plant. Once the DCS converts the process information to personal computer language, it can be distributed to everyone on the plant site and to other parts of the organization that may be located anywhere in the world.

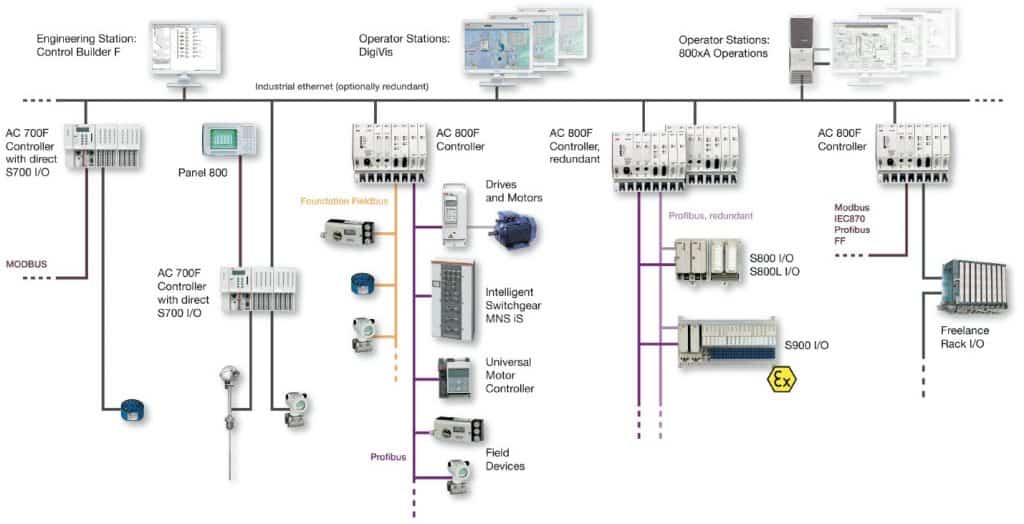

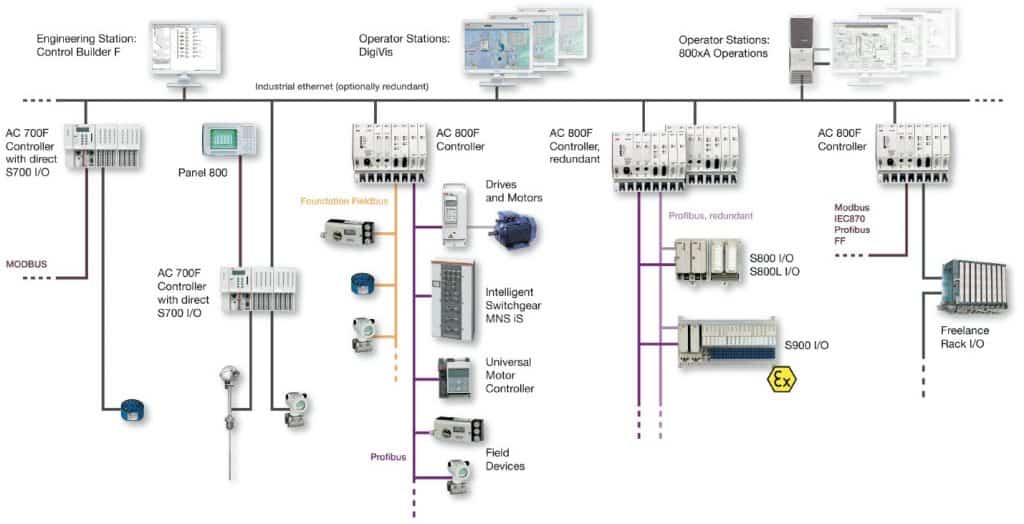

A type of automated control system that is distributed throughout a machine to provide instructions to different parts of the machine. Instead of having a centrally located device controlling all machines, each section of a machine has its own computer that controls the operation. For instance, there may be one machine with a section that controls dry elements of cake frosting and another section controlling the liquid elements, but each section is individually managed by a DCS. A DCS is commonly used in manufacturing equipment and utilizes input and output protocols to control the machine.

In a dynamic global industry like oil and gas, you need to manage costs, extract the most value possible from current assets and maximize up-time. Technology available today makes it possible to develop a truly connected enterprise and move closer to operational excellence. Cloud, mobility and analytics offer an actionable view into real-time production data so you can respond to issues as soon as they arise, from anywhere in the world.

Improvements in production can translate into increased efficiency and productivity. Whether you would like to reduce your energy consumption, upgrade legacy systems or make better use of the data you generate, we have the oil and gas equipment and resources you need to meet your goals.

Improvements in production can translate into increased efficiency and productivity. Whether you would like to reduce your energy consumption, upgrade legacy systems or make better use of the data you generate, we have the oil and gas equipment and resources you need to meet your goals.

In this course participants will learn about the main characteristics of the DCS systems. They will become familiar with the DCS hardware and how it is connected together to make up the basis of the DCS. Once the hardware is installed and tested, the participants will learn about programming the DCS software. Once the software is configured the participants will become familiar with the DCS accessories, such as alarm and data reporting systems.

DCS displays information on a computer and allows process operators to run the process, making the process information available to other people in the plant. Once the DCS converts the process information to personal computer language, it can be distributed to everyone on the plant site and to other parts of the organization that may be located anywhere in the world.

DCS displays information on a computer and allows process operators to run the process, making the process information available to other people in the plant. Once the DCS converts the process information to personal computer language, it can be distributed to everyone on the plant site and to other parts of the organization that may be located anywhere in the world.A type of automated control system that is distributed throughout a machine to provide instructions to different parts of the machine. Instead of having a centrally located device controlling all machines, each section of a machine has its own computer that controls the operation. For instance, there may be one machine with a section that controls dry elements of cake frosting and another section controlling the liquid elements, but each section is individually managed by a DCS. A DCS is commonly used in manufacturing equipment and utilizes input and output protocols to control the machine.

In a dynamic global industry like oil and gas, you need to manage costs, extract the most value possible from current assets and maximize up-time. Technology available today makes it possible to develop a truly connected enterprise and move closer to operational excellence. Cloud, mobility and analytics offer an actionable view into real-time production data so you can respond to issues as soon as they arise, from anywhere in the world.

Improvements in production can translate into increased efficiency and productivity. Whether you would like to reduce your energy consumption, upgrade legacy systems or make better use of the data you generate, we have the oil and gas equipment and resources you need to meet your goals.

Improvements in production can translate into increased efficiency and productivity. Whether you would like to reduce your energy consumption, upgrade legacy systems or make better use of the data you generate, we have the oil and gas equipment and resources you need to meet your goals.In this course participants will learn about the main characteristics of the DCS systems. They will become familiar with the DCS hardware and how it is connected together to make up the basis of the DCS. Once the hardware is installed and tested, the participants will learn about programming the DCS software. Once the software is configured the participants will become familiar with the DCS accessories, such as alarm and data reporting systems.

- Day 1

Distributed Control Systems (DCS)

- Introduction

- Basic concepts of DCS

- DCS specifications and selection criteria

- Control system and security hierarchy

- DCS implementation

Day 2

DCS Hardware

- Block diagram

- Hardware

- Communication

- Hardware security and redundancy

Day 3

DCS Software

- Control system configuration

- Controller configuration

- Function block configuration

Day 4

DCS Accessories

- Alarm system management

- Reporting

- Diagnostics

- Typical DCS Systems

More to watch : http://www.youtube.com/watch?v=EkXcUfeFyIM

No comments:

Post a Comment